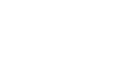

PA66 black virgin, PA66, Nylon 66, Polyamide 66, Engineering Polymers

PA66 black virgin , PA66, Nylon 66, Polyamide 66, Engineering Polymers PA66 glass fiber reinforced nylon is made of PA66 resin and filled with 10-40% glass fiber. It is of high strength, durability, wear resistance and corrosion resistance. In addition, the material is dimensionally stable with high temperature thermal deflection, good ...

Description

PA66 black virgin , PA66, Nylon 66, Polyamide 66, Engineering Polymers

PA66 glass fiber reinforced nylon is made of PA66 resin and filled with 10-40% glass fiber. It is of high strength, durability, wear resistance and corrosion resistance. In addition, the material is dimensionally stable with high temperature thermal deflection, good electrical insulation, good smooth surface, easy molding and other advantages. RoHS approved material is compliant and can be widely used in auto parts, electrical equipment, power tools, gears, mechanical parts and other fields.

Specification:

| Item | Typical Characteristic | Testing Standard | ||||||

|

密 度 Density |

1.18g/cm3 | ASTM D-792 | ||||||

| æˆåž‹æ”¶ç¼©çŽ‡ Molding Shrinkage | 1.0-1.5% at 23℃ |

ASTM D-955 | ||||||

|

å¸æ°´çŽ‡ Water Absorption |

8.50% | ASTM D-570 | ||||||

| å¸æ¹¿æ€§ Moisture absorption |

2.30% | ASTM D-570 | ||||||

|

拉伸强度 Tensile Strength |

86MPa | ASTM D-638 | ||||||

| æ–裂伸长率 Elongation at break |

2.0-5.0% at 10mm/min |

ASTM D-638 | ||||||

|

弯曲强度 Flexural Strength |

105MPa | ASTM D-790 | ||||||

|

å¼¯æ›²æ¨¡é‡ Flexural Modulus |

2970MPa | ASTM D-790 | ||||||

|

悬臂æ¢ç¼ºå£å†²å‡»å¼ºåº¦ Izod Notched Impact Strength |

36J/m | ASTM D-256 | ||||||

| 摩擦系数 Friction Coefficient |

0.2 +73□H(+23℃) Static |

Thrust Washer Test3 | ||||||

| 摩擦系数 Friction Coefficient |

0.35 +73□H(+23℃) Dynamic |

Thrust Washer Test3 | ||||||

|

熔点 Melting Point |

260℃ | ASTM D-3418 | ||||||

|

çƒå˜å½¢æ¸©åº¦ Heat Deflection Temp |

230℃ | ASTM D-648 | ||||||

Processing:

Molding Injection

| Item | DIN Method | Units | Valus |

| Density | D 53479 | g/cm3 | 1.13 |

| Mold Shrinkage | D 53464 | Mm/mm | 0.013 |

| Tensile Strenght | D 53455 | Mpa | 80 |

| Strain at break | D 53455 | % | 25 |

| Flexural Strenght | D 53452 | Mpa | 100 |

| Flexural Modulus | D 53457 | Mpa | 2700 |

| Izod impact Strenght | D 53453 | KJ/m2 | 4.4 |

| Dielectric Strength | D 53481 | kv/mm | 20 |

| Melting Point | --- | °C | 260 |

| Fire Resistance | UL 94 | HB | -- |

| Filler | Method for ignition |

% | 30 |

Packing: 30Kg/1000 kg net bags as customer request

Product usage:

It serves as an ideal raw material for automobile parts, ribbonsports goods,

plug connector, Instrument equipment

With ISO9001:2015, OHSAS18000, ISO14001, TS16949 Quality Management system certification of partial products, all materials applied have been certified by such authoritative organizations as SGS and have passed ROHS and REACH to ensure that clients acquire high-quality material.